Troubleshooting with data analysis

I got a call from the ring mill operator

of my company.

He told me that the main roll stopped

rotating while rolling a ring.

But the main roll was rotating when I

arrived at the ring mill shop.

I

wasn’t at the sight so I couldn’t see the problem.

I looked over the technical data saved in

the PC.

And I

could find the cause of this problem as soon as I saw the data.

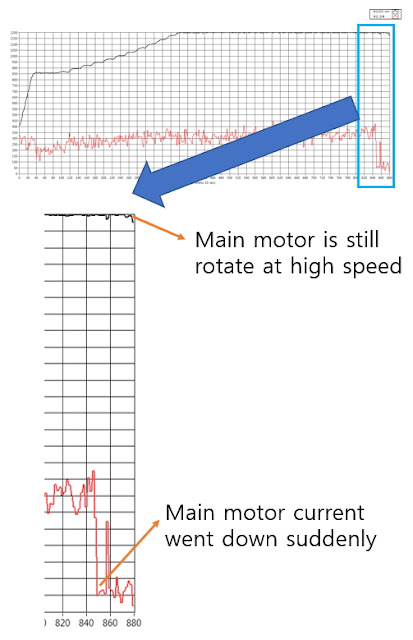

* Technical data of CALTEK ring mill

I found the main motor was rotating at

high speed and the motor current went down suddenly.

If the motor is over current, it could be

stopped.

But the current is not high in this case.

I could guess the motor had no problem,

it was normal.

But why didn’t the main roll rotate?

There’s a gear box between main motor and

main roll.

It transfer the motor’s driving power to

the main roll.

Motor rotates but main roll doesn’t

rotate. I can guess there’s something

wrong in the gear box.

We checked the gear box and found the

coupling connecting the motor and gear box has been broken.

We replaced the broken coupling with new

one.

We can find the cause of the trouble and

solve it fast and easily with the technical data.

I can’t imagine to operate the ring

rolling machine and manage lots of troubles without the data.

We might have spent many hours to find

the cause of the trouble today if there’s no data.

CALTEK ring rolling machine provide the

data logging.

Our program saves almost all of the

sensor data in real time.

The data is very helpful when you have

trouble with the machine and try to solve the problem.

x

Comments

Post a Comment